COMPOUNDER 2x72 48 LD

COMPOUNDER 2x72 48 LD

Contact us for price

or

Call + 39 015 590446

Description

COUMPOUNDING LINE type AD-S 75

- Including twin screw extruder with 2x72 mm co-rotating parallel segmented intermeshing screws L/D 48

- screws design will be made by our Technicians

- Screw element material W6 anti-abrasive

- Cylinder barrels with full Inliner made in α101 (Chrome-nickel carbide steel )

- Screw shafts made from WR15 vanadium Alloy steel

- Max screw speed up to 600 rpm.

- 250 kw a.c.drive

- Gear-box with R+W safety coupling

- n.3 venting points, 1 with 3,0 kw vacuum pump, including condensate collector

- 2x side feeders type ZSB (twin screw) 1 x 0,62 mm. each one a.c.3,0 kw drive, including hopper loader with internal stirring unit ( for anti-bridging of additives / fillers as powders, fibers, … )

- Water cooling/tempering unit for cylinder-barrels,

- incl. tank, Temperature-sensor, circulation-pump and heat-exchanger

- semi-automatic, non-stop 2-piston screenhanger

- hydraulic unit

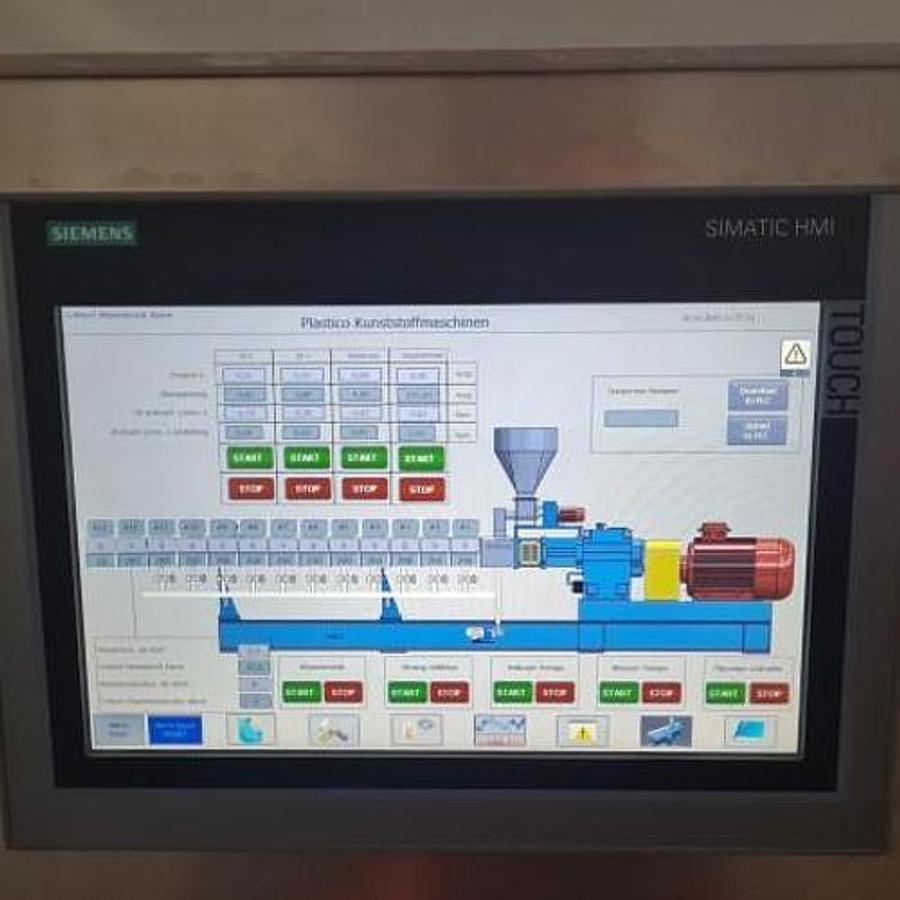

- Siemens PLC with touch screen (EN+DE) and ABB main control board.installed and actually running with Sikoplast WRG pelletizing unit for trials Strand-die-head

- Strand cooling water bath

- incl., process water filters, circulation-pump and Temperature-sensor and

- heat-exchanger ( > to be connected with main-chiller – not included !)

- Strand-pelletizer ST type A-SG 200

- Drive 7,5 kW – AC

- Parker FU converter Type AC 10

- Hard-metal cutting rotor knifes 32 teeth – vertical cut

- Pizzato security Lock

- Pneumatic pressure device ( > Air compressor 2 – 4 bar NOT included)

- incl. 1x spare cutting rotor, 1x pressure roller and 1x stator-blade

- Vibro classifier

- Working width 600 mm x Length 1.600 mm

- 3-decks stainless steel sieves

- Trial-runs possible

Specifications

| Manufacturer | EUROPEAN |

| Model | 2x72 mm.parallel, co-rotatig, segmented screws (bespoke design feasible) |

| Year | 2024 |

| Condition | New |

| Stock Number | GEMR102 |

| installed power - used power in work: about 60-65% | 250 |

| availability | 2 months ca |

| options available | strand OR water ring OR underwater pelletizer - Start-up & Training in your Factory with 2 Technician approx.. 3-4 days plus 2 Travel /flight days |

| capacity | 600 kg/h depending on materials and feeding rate |

| conditions | as new |