ITALIAN UNDERWATER PELLETIZER 1.400 kg/h rigid and soft PP max 30 MFI

ITALIAN UNDERWATER PELLETIZER 1.400 kg/h rigid and soft PP max 30 MFI

Contact us for price

Description

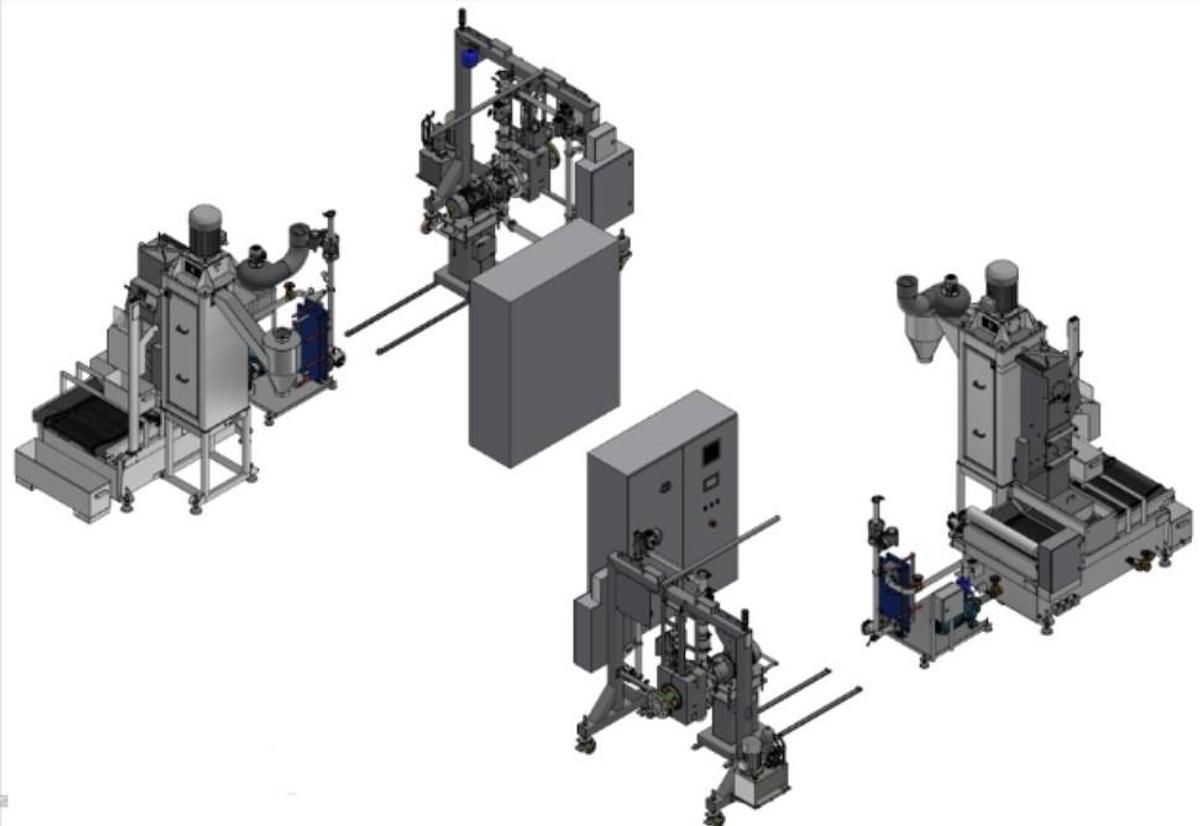

UNDERWATER PELLETIZER

up to 1.400 kg/h with soft and rigid PP max 30 MFI

Total installed power 67,14 kW

The supply includes:

Connection from your screen changer to the diverter valve, made of C45 steel heated by mica electric haters.

Diverter valve heated with electric heaters This allows the flow of product to be diverted to the drain to bring the extruder up to speed, it consists of a C45 steel body with a specially perforated plate that diverts the flow to the outlet or die. This plate slides via a position-controlled hydraulic cylinder, operated by a hydraulic power unit complete with high-pressure hoses. Pressure and product temperature control probes are also included.

Cutting unit consisting of: electrically heated die adapter/diverter valve; AISI304 granulation chamber; die with hard metal inserts, heated by electrical heaters; auger holder unit with blade pressure adjustment on the die via an air piston and regulator. 7,5 kW drive

Bypass with AISI304 piping system complete with support trolley and electrically controlled pneumatic valves, which keeps the circuit running. It also allows for precise timing of water introduction into the granulation chamber.

Static separator constructed of in AISI304 stainless steel where the water is first drained from the granules. It can be opened for cleaning, with drawer screens. The drained water, along with that separated by the centrifuge, falls directly onto the filtering surface of the belt filter. Lumps are discharged via a damper.

Ø 450 mm. 3-stage vertical centrifuge in AISI304 stainless steel, 7,5 kW drive, with removable doors for internal inspection and cleaning. Equipped with coded magnetic safety microswitches. Internal water-granule separation basket consisting of 4 removable stainless steel mesh screens.

Air exhaustion electric fan inside the perforated basket, complete with manually adjustable butterfly valve. External soundproofing with sound-absorbing and anti-drum panels, covered with an external containment protection.

Soundproof, AISI304 stainless steel granule discharge cyclone,with anti-drum panels, covered by an external containment protection.

Fabric dust filter.Water from the static separator and centrifuge is discharged onto the filtering surface of the fabric. When the liquid level in the discharge area increases due to excessive impurities, a sensor sends an electrical pulse to a gearmotor that advances the clogged section of fabric, replacing it with a clean one. This automatically initiates a new filtration cycle. The filtered water falls into the collection tank below, which also serves as a support for the above-mentioned filter. An additional tray collects the used non-woven fabric.

AISI304 stainless steel Water collection tank, with a load-bearing structure, equipped with a kit of immersion heaters for water pre-heating; level indicator and electrically controlled pneumatic valve for restoring the water level; electric suction pump that sends water through a plate heat exchanger (complete with ON-OFF valve for your cooling circuit) and directly to the granulation chamber. Endress+Hauser water flow meter: in the event of a blockage of the heat exchanger or granulation chamber, an alarm is sent to the PLC, which automatically interrupts the flow of material via the diverter valve and diverts the water flow directly into the centrifuge via the bypass valve.

Control Panel, equipped with a ventilation system with a manually adjustable thermostat. The granulator is managed by a Siemens PLC model S7 1500, in fail-safe version. Control operations are performed via a 15" touch-screen operator terminal located on the granulation unit box. A remote assistance system that, via an Internet connection (not included), allows the status of certain parameters/settings to be checked, errors to be detected, modifications to be made, and software maintenance to be performed. A UPS unit that, in the event of a sudden power outage, allows the diverter valve to be set to the discharge position, preventing the molten material from advancing and filling the granulation chamber and related pipes. Data exchange system between PLC/client PC (PLC/PC with suitable software system provided by the user) and PLC. Profinet protocol

Advantages: Material flows without undergoing any changes.

Reduced pressure drop due to the short path between the filter and the die

Easy cleaning when changing colors resulting in less material waste

Reduced water consumption and improved water quality

.

Specifications

| Manufacturer | ITALIAN |

| Model | UNDERWATER PELLETIZER 1.400 kg/h rigid and soft PP max 30 MFI |

| Condition | New |

| Stock Number | MEV100 |

| installed power - used power in work: about 60-65% | 67,14 |

| availability | 110 working days from confirmation |

| options available | Diathermic oil heated die for a quicker heating to the die core- with heating unit |

| capacity | 1.400kg/H |

| conditions | new machine |

| type | underwater |